Direct to Fabric (DTF) printing has emerged as a revolutionary technology for commercial apparel decoration, offering unparalleled versatility and efficiency. By enabling direct application of designs onto various fabrics with precision and speed, DTF printers empower businesses to create complex, vibrant designs at competitive prices. This game-changing method is transforming the market by providing fast production times, lower costs, minimal waste, and high-quality results, making it an attractive option for small businesses and startups looking to compete on a larger scale in the apparel industry.

“The world of commercial printing is undergoing a significant transformation with the advent of Direct-to-Fabric (DTF) technology. This cutting-edge approach to fabric printing offers businesses a competitive edge by streamlining production, enhancing quality, and expanding design possibilities. In this article, we explore the key innovations that are shaping modern Commercial DTF Printing, from the historical evolution of the technique to recent advancements in ink, substrates, and digital integration.”

- The Rise of Direct-to-Fabric (DTF) Technology

- – A brief history and evolution of DTF printing

- – Key advantages over traditional printing methods

The Rise of Direct-to-Fabric (DTF) Technology

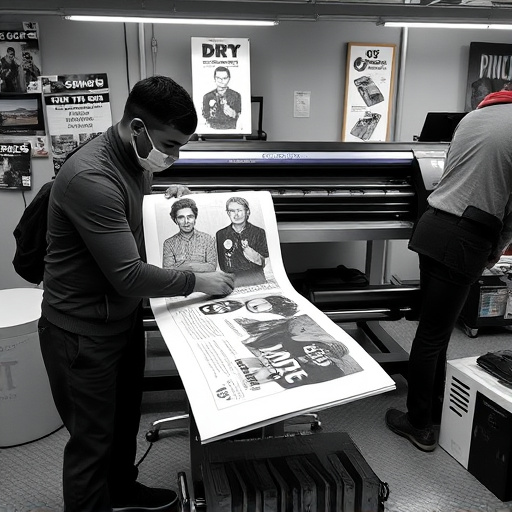

Direct-to-Fabric (DTF) technology has emerged as a game-changer in the printing industry, transforming commercial DTF printing into a versatile and efficient process for clothing brands and designers. This innovative approach eliminates the need for intermediate materials, enabling direct application of designs onto various fabric types. With a DTF printer, custom sheets become the canvas for heat pressing intricate logos and artistic patterns onto garments with precision and speed.

The rise of DTF printing has revolutionized the way businesses create and mass-produce branded apparel. It offers unparalleled versatility, allowing for complex designs, vibrant colors, and a wide array of fabric options. This technology is particularly beneficial for small businesses and startups, providing them with the tools to compete on a larger scale by offering custom, high-quality clothing at competitive prices.

– A brief history and evolution of DTF printing

Direct to fabric (DTF) printing has emerged as a game-changer in the garment decoration industry, offering a high-quality, efficient method for customizing apparel. Its history traces back to the late 20th century when advancements in inkjet technology laid the foundation for this innovative process. Initially, DTF was used primarily for small-scale, personalized printing on various materials, including fabric. Over time, as technology evolved, printers began exploring its potential for commercial applications, particularly in the realm of t-shirt decoration.

Today, DTF printing for t-shirts is a thriving sector, with businesses leveraging custom sheets and specialized dtf transfer film to create intricate heat-pressed designs on garments. This method provides an array of benefits, such as vibrant colors, fine detail reproduction, and the ability to print on various fabrics, revolutionizing how apparel brands and designers approach customization. The evolution of DTF printing continues, pushing the boundaries of what’s possible in commercial garment decoration.

– Key advantages over traditional printing methods

Commercial DTF (Direct to Fabric) Printing is revolutionizing the apparel industry by offering a range of key advantages over traditional printing methods. One of the most notable benefits is its versatility; DTF allows for high-quality printing on various fabric types and shapes, making it ideal for custom graphic tees and other garments. This method directly applies ink to the fabric surface, ensuring vibrant colors and detailed designs that are durable and long-lasting.

Compared to screen printing or digital printing, DTF provides faster production times, reduced set-up costs, and minimal waste. The process is highly efficient as it doesn’t require separate plates or screens for each color, eliminating the need for intricate setup procedures. Additionally, DTF heat transfer paper ensures easy application of designs, enabling businesses to quickly turn around orders for dtf for Custom graphic tees and other promotional products.

As we’ve explored, commercial DTF printing has emerged as a game-changer in the textile industry. With its direct application to fabric, this technology offers unparalleled efficiency, cost-effectiveness, and design flexibility compared to traditional methods. Key innovations in ink formulations, printhead technologies, and digital design software continue to push the boundaries of what’s possible in DTF printing, making it an increasingly viable option for a wide range of applications. From custom apparel to on-demand signage, the future of commercial DTF printing looks bright, promising to revolutionize the way we bring designs to life on fabric.